Products 製品情報

Overview

Rigid series, Our entry level products.

This range of products are lighter having a simpler damping system and corner joints. This focus o “light weight, rigidity, and damping” delivers a similar characteristic sound signature to our flagship range.

Be under no illusion as a rack it thoroughly pursues maximum sound quality, We have been building this series for over 10 years and is still considered by many of our clients as being more than good enough for their systems.

Options

1. Rigid Tower

Board Size : 600 x 480mm

| Total height | 860mm | 680mm | 500mm |

| 6 shelves | RT 866 | ||

| 5 shelves | RT 865 | RT 685 | |

| 4 shelves | RT 864 | RT 684 | RT 504 |

| 3 shelves | RT 683 | RT 503 | |

| 2 shelves | RT 502 |

2. Rigid Tower “Mid”

Board Size : 520 x 410mm

| Total height | 860mm | 680mm | 500mm |

| 6 shelves | RT 866 Mid | ||

| 5 shelves | RT 865 Mid | RT 685 Mid | |

| 4 shelves | RT 864 Mid | RT 684 Mid | RT 504 Mid |

| 3 shelves | RT 683 Mid | RT 503 Mid | |

| 2 shelves | RT 502 Mid |

3. Rigid Table

All tables have a standard heights of 465mm

| Board Size | 600×480 mm | 520×410 mm | 470×370 mm |

| 1 shelf | ALT 600 | ALT 520 | ALT 12 |

4. Rigid Base

| Board Size | 600×480 mm | 520×410 mm | 470×370 mm |

| Height 90mm | ALB 600 | ALB 520 | ALB 12 |

| Height 130mm | ALB 600 / 2 | ALB 520 / 2 | ALB 12 / 2 |

Spike mounts we recommend

- SM-5X / B4 ( Black / Over 25kg )

- SM-5X / P4 ( Polished / Over 25kg )

- SM-5TX / P4 ( Hi end model / Over 25kg )

- SM-3TX / P4 ( Under 25kg )

Dimensions

Load capacity

Rigid Tower

- Total : 250kg

- 50kg per a Normal shelf : Equipment with 4 legs ( 80kg per a Thick shelf : Equipment with 4 legs )

- 40kg per a Normal shelf : Equipment with 3 legs ( 70kg per a Thick shelf : Equipment with 3 legs )

Rigid Table

- Total : 160kg

- 50kg per a Normal shelf : Equipment with 4 legs ( 80kg per a Thick shelf : Equipment with 4 legs )

- 40kg per a Normal shelf : Equipment with 3 legs ( 70kg per a Thick shelf : Equipment with 3 legs )

Rigid Base

- 50kg with a Normal shelf : Equipment with 4 legs ( 80kg with a Thick shelf : Equipment with 4 legs )

- 40kg with a Normal shelf : Equipment with 3 legs ( 70kg with a Thick shelf : Equipment with 3 legs )

Details

Lightweight thin walled large radius titanium pipe giving outstanding rigidity

The frame uses a titanium pipe with a diameter of 25mm and a wall thickness of 1mm.

- Lightweight, more easily damped.

- High strength

- Non-magnetic

- Naturally responsive to damping.

- Resistant to rust

- Seamless pipe without joints ensuring long term performance.

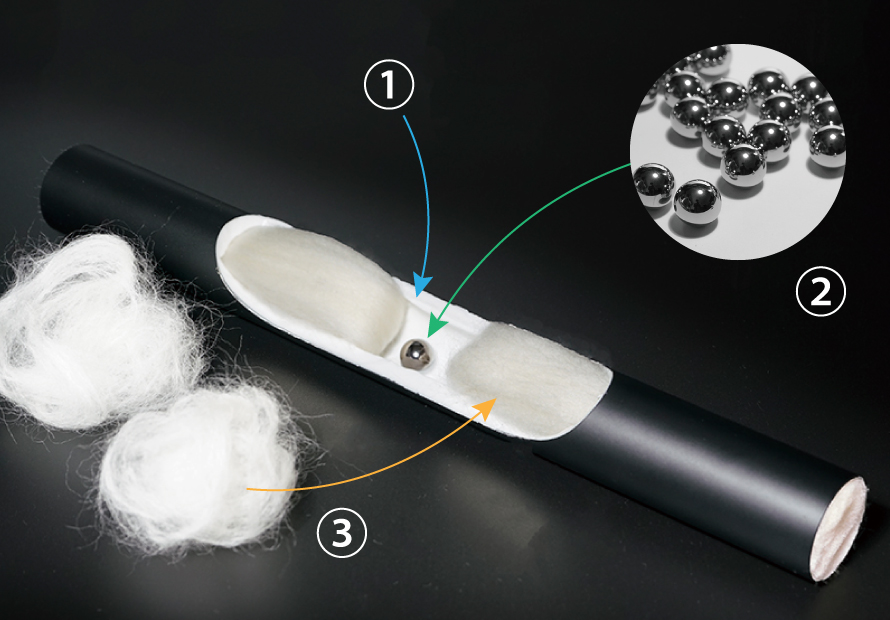

Our Internal pipe damping system

Internally all the Titanium pipes are fully damped by three discrete damping treatments. These treatments have all been optimised to damp effectively but at the same time minimise any additional increase in weight.

1. Two layers of damping silicone

Internally all the titanium tubes have two layers of damping silicone compound applied. These two coats greatly reduce skin vibrations passing over the length of the tube.

2. Cancel weight

A “Cancel ball” is attached onto the inner wall of the pipe and held in place by the silicon coating. This weight has some limited degree of movement and when bonded to the pipe they interact and further cancel vibration. This is a process brought across from our Silent Mount Technology.

3. Sound absorbing material

Australian wool is inserted into the cavity to prevent internal resonance. As well as being lightweight material that is exceptionally efficient at this type of damping.

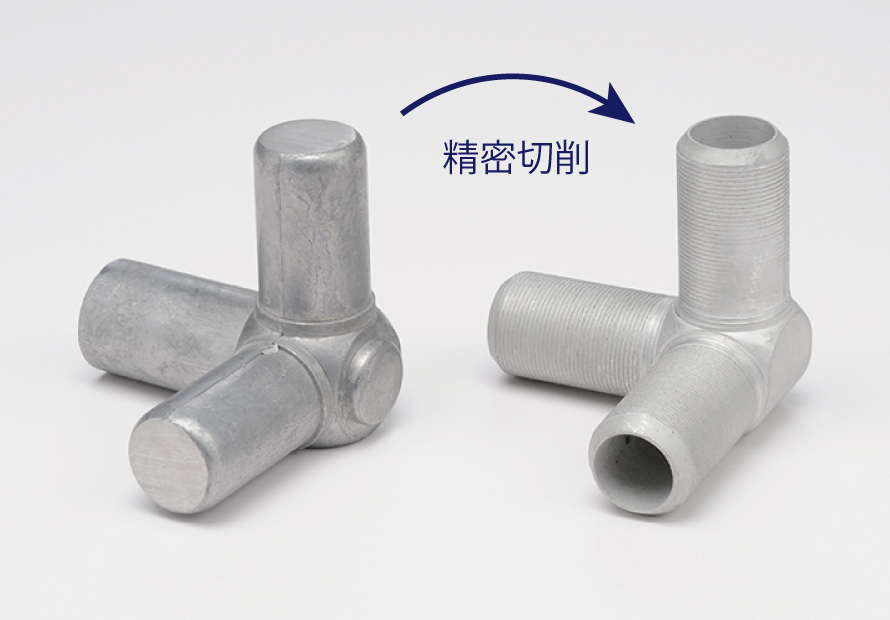

Aluminum die-cast “Corner joint”

The 3-way (2-way) “corner joint” used at the corner of the frame is manufactured by precision machining of an aluminium die cast par. It was designed to offer a very rigid connection with the lightest of structures.

The tube mating surfaces have been grooved to maximise the bond strength achieved with the structural glue.

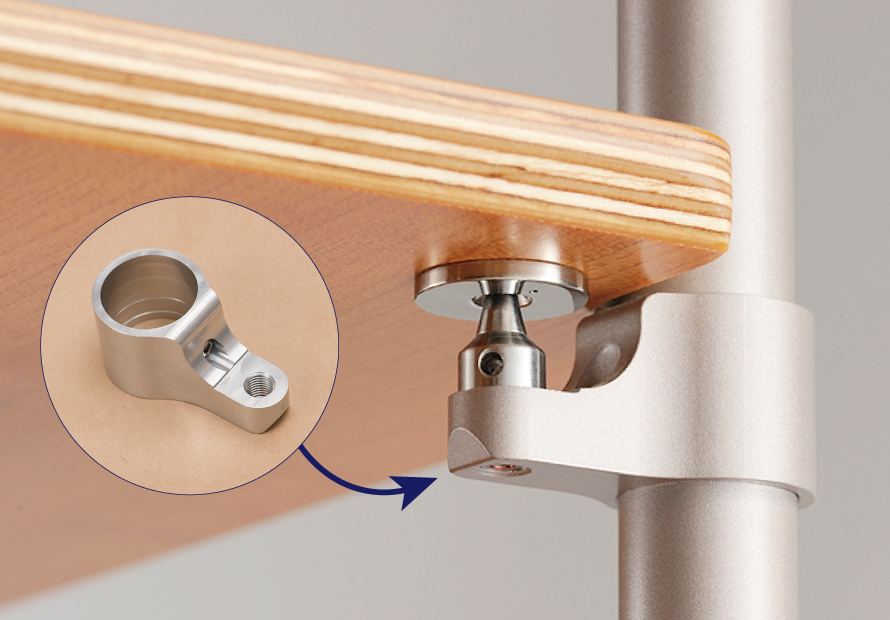

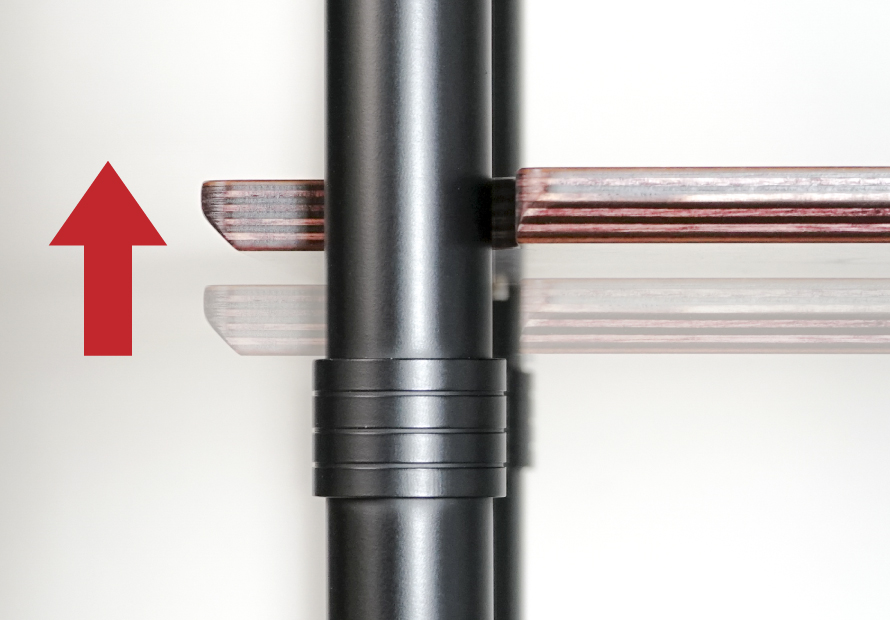

Shelf support

Every shelf support is manufactured from duralumin and machined to the same exacting tolerances.

Alignment of the shelf mounting brackets is rigorously controlled both height and orientation.

Why Structural adhesives for the frame connections

We avoid welding or screws in the frame construction neither system give the quality of connection that we require.

- Welding : by its very nature and the heat required after assembly and cooling of the joints. The frame is left under tension. In extreme cases this can result in distortion of the frame. This has a number of effects. The first is that the heat will damage the damping components that we know work best. The second is the tension really affects the final performance of the frame.

- Screws : these provide only point connection and on curved surfaces results in distortion and points of limited contact that can give rise to buzzing type vibration. Screws are also prone to loosening over time. Finally temperature changes can significantly alter the strength of the connection

Glue ( 3M™ Scotch-Weld™ Structural Glue DP-460 ) : High-strength structural glue gives a total bond around both of the parts of the joint. It fills any small voids to prevent buzzing type noise. It is also relatively low mass so keeps the frame light! Finally like the silicone coatings on the inside of all the tubing it has a damping effect at the joint without introducing temperature related stress.

Modern adhesives are incredibly strong and very consistent in performance. They are often used in aerospace construction where low weight is high strength is essential. The adhesive we have selected is temperature stable and long lasting.

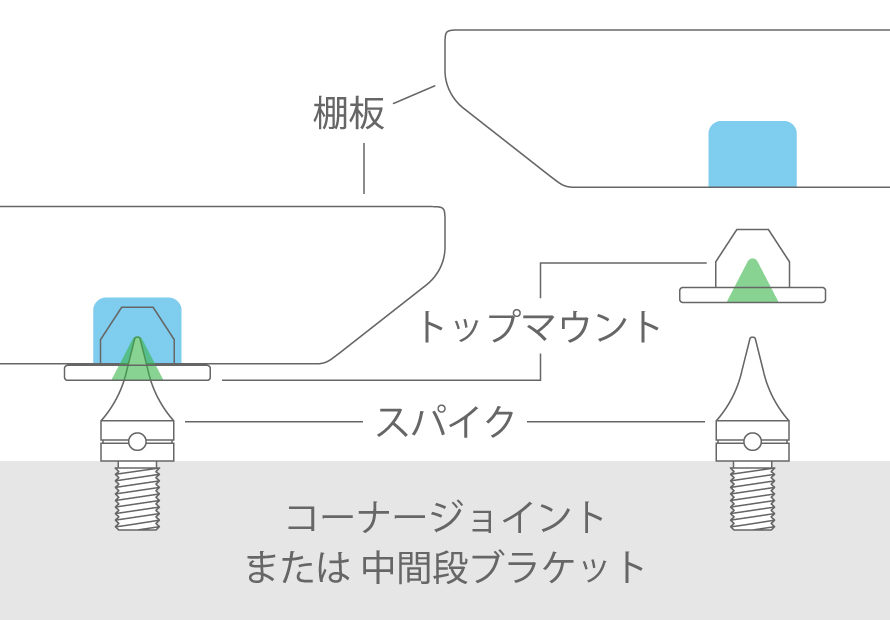

Spike support system

Spikes and “TopHats” are used for the support of each shelf board. This spike support system has two main advantages.

Reduction of vibration transmission

Between devices on the rack through the frame in between the boards. As well as transmission of structural vibration through the surface that the frame is resting on.

Stable installation

The spike TopHat system controls vibrations between the frame and the board. The clear mechanical grounding also effectively damps any vibrations when they are present.

To date this spike/TopHat system is still the best way to limit the transmission of vibrations within our racks.

The whole frame can be leveled and made rigid by adjusting the four bottom spikes. These spikes have a very fine pitch (the distance the screw travels in one rotation) is finer than usual. This means that when tightening after final adjustment no loss of rigidity or level occurs when holding the spike with the bar and spanner provided.

As an option, we offer a high-performance Titanium “TopHat” for the spike receiver for the shelf plate (stainless steel is included as standard).

As an option, we offer long spikes

- 10mm:Long Top Spike 10

- 20mm:Long Top Spike 20

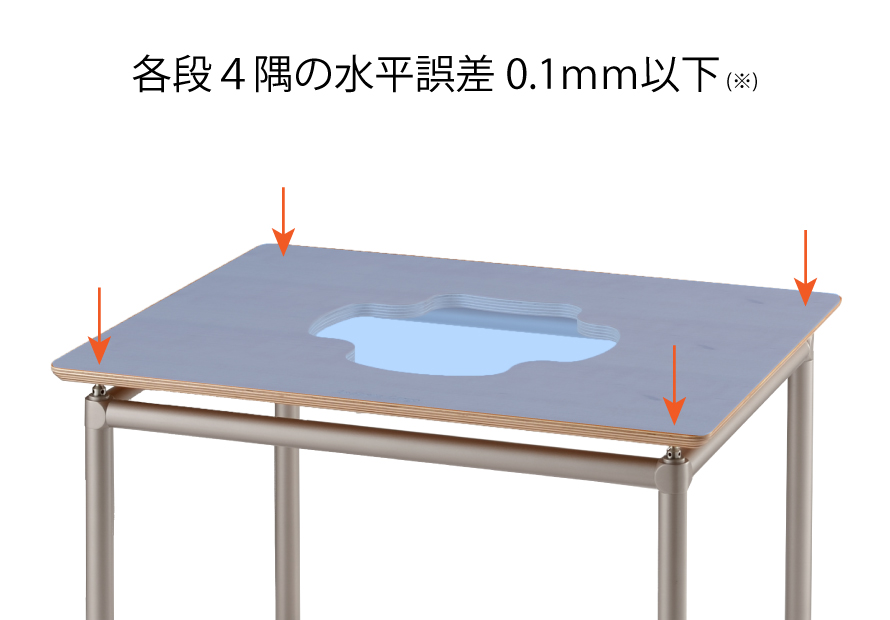

Alignment

All frames are fully jigged during assembly. For each shelf the spike supports alignment is within 0.1mm.

The spikes for the shelves and the “Tophats” that receive them are selected from about 1,000 spikes and matched with a digital vernier caliper (with an accuracy of 0.01 mm) to use. This is an essential in ensuring a perfect support for your equipment.

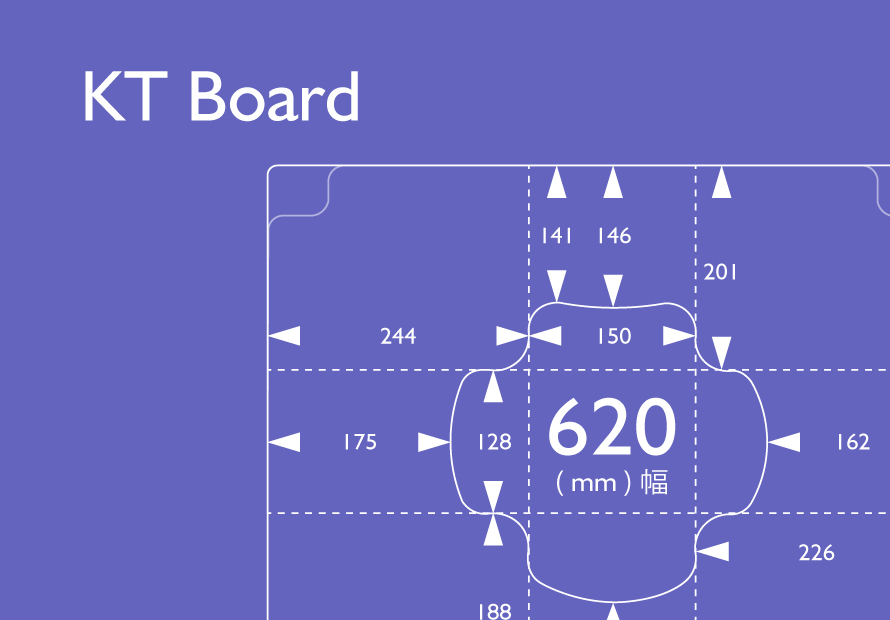

Shelves machined from a tuned laminated plywood.

The mechanical properties of this laminated plywood have been selected to balance between rigidity and retaining the ability to absorb the airborne energy from the audio.

The central opening cut into the boards themselves in addition to reducing the weight also prevents resonance between the base of the equipment and the board surface, in order to dampen and reduce the weight of the shelf board itself, and to prevent resonance between the equipment and the shelf surface.

Please Note : Various hole sizes and shapes are available for the board. The boards are also available in 2 thicknesses and 3 colours.

Color options

- Boards : 3 colours

- Frames : 2 colors

Reference

Contact

ニュースNews

- 2025.01.23

- お知らせ

- PhonoARAY 試聴レビューが公開されました

- 2025.01.10

- お知らせ

- PrimoBoard 試聴レビューが公開されました

- 2025.01.06

- お知らせ

- あけましておめでとうございます

- 2024.12.27

- お知らせ

- 2024-2025 年末年始休業のお知らせ

- 2024.11.21

- プレスリリース

- 2024年 冬 新製品情報② Chord Company PhonoARAY