Products 製品情報

Overview

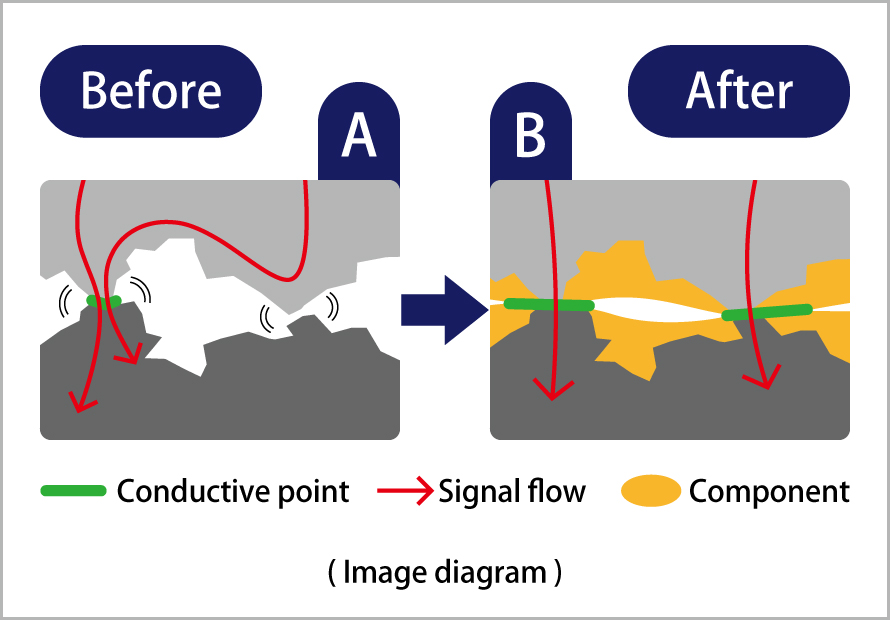

Even on the best looking contact surfaces the contact points of the plug and socket surface may look shiny to the naked eye. The reality is that there are limited points of actual direct contact (see figure A). This limited contact affects efficiency and therefore the quality of the connection. In addition to this the contact will be more prone to microphony for both audio and video signals.

The Super TMD is based around a conductive polymer. This polymer is applied as a liquid and smoothes over the minute irregularities on the treated surfaces. This greatly increases the effective contact area reduces microphony greatly enhancing the signal transfer and stability of the connection.(See figure B)

Super TMD is recommended for a wide range of audio and video equipment especially those handling either small signal such as cartridge connections and those handling very high frequency signals.

Plug types include, speaker terminals RCA / XLR / BNC / USB / LAN /cartridge and tonearm connections / loudspeakers / amplifiers/ power supplies / vacuum tubes, etc.

OPTIONS

For best results use before use by date shown on the bottom of the package ( 2 years )

STMD ( Super TMD)

Complete with several sample cotton buds applicators and paper tissues

- STMD – 1.5・・・ 1.5ml

- STMD – 3 ・・・ 3ml

- STMD – 10・・・10ml

| Size | STMD-1.5 | STMD-3 | STMD-10 |

|  |  |

Application

- BEFORE USE PLEASE read the instructions carefully and observe any precautions. Taking time to apply the product carefully will ensure long lasting upgraded connections.

- SHAKE BOTTLE WELL BEFORE EVERY APPLICATION. This ensures a thorough mixing of all the components within the SuperTMD.

Step1

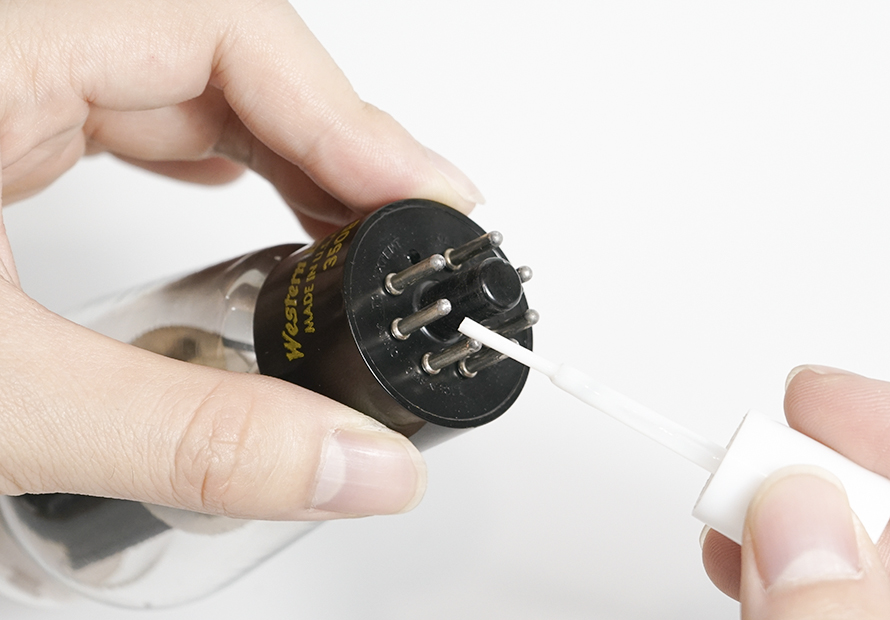

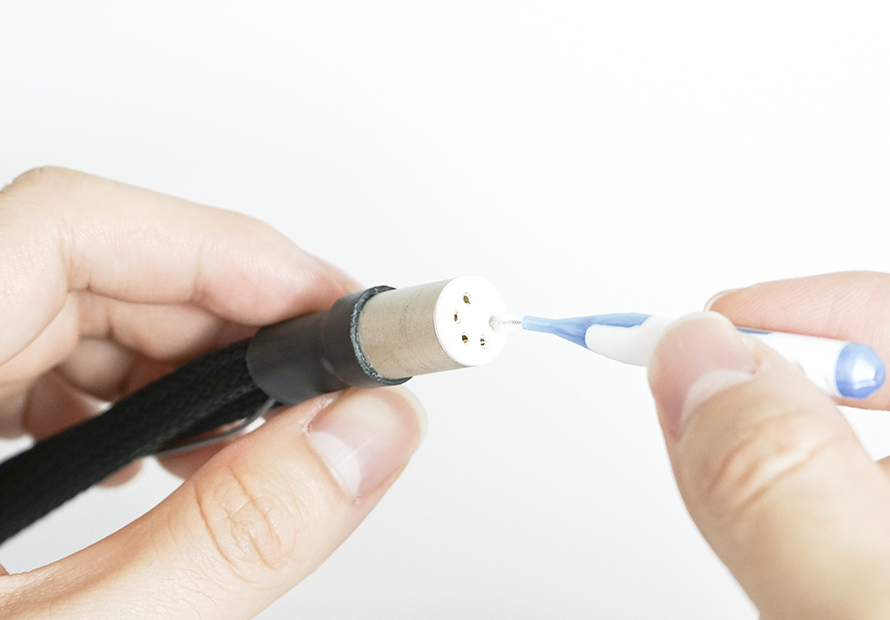

SuperTMD needs to be applied as sparingly as possible. There is no benefit in applying excessive quantities.

ONLY TREAT THE METAL CONTACT SURFACES OF THE CONNECTORS

Any SuperTMD spilt onto the insulation surfaces should be wiped off before drying. It is important not to promote conduction between connector pins that are intended to be isolated from each other.

Step2

ALWAYS Allow 10 minutes bonding / drying time after application.

Remove the excess dried residue from the contact surface using a cotton bud or similar.

TIP

- When inserting or removing our supplied cotton buds from smaller female terminals, rotate it clockwise (this prevents the buds from unraveling inside the terminal).

- For maximum long term protection and optimum contact performance, REPEAT treatment after one hour.

- For terminals that are heavily soiled it makes sense to pre-clean the contacts with the cleaner.

- When you hear the improvement to your system we have found that keeping this peak contact performance requires a follow up application no sooner than six months after the first treatment.

Youtube

Reference

Contact

ニュースNews

- 2025.01.23

- お知らせ

- PhonoARAY 試聴レビューが公開されました

- 2025.01.10

- お知らせ

- PrimoBoard 試聴レビューが公開されました

- 2025.01.06

- お知らせ

- あけましておめでとうございます

- 2024.12.27

- お知らせ

- 2024-2025 年末年始休業のお知らせ

- 2024.11.21

- プレスリリース

- 2024年 冬 新製品情報② Chord Company PhonoARAY